Special rolling technology since 1899

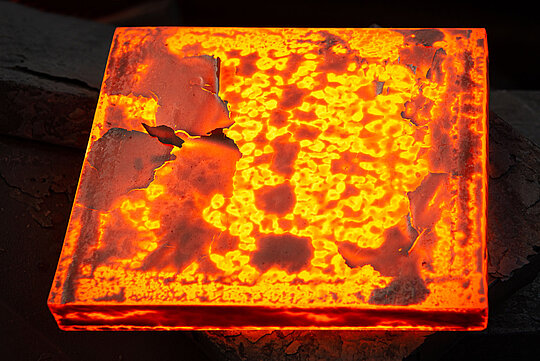

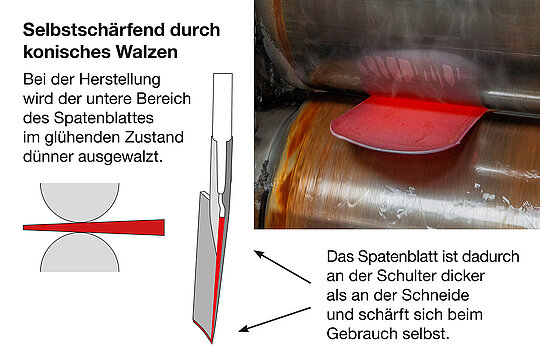

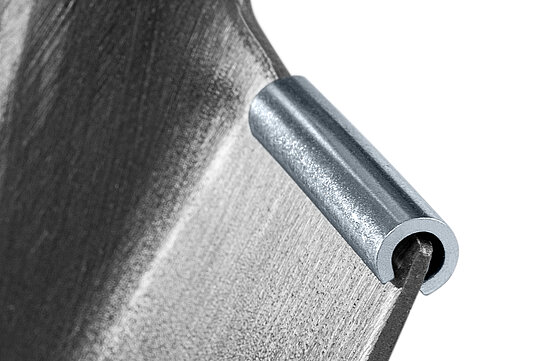

The IDEAL spade is our premium product and has been manufactured in traditional and handcrafted work since 1899. Eight employees produce a spade of the highest quality from a steel block in up to 20 work steps. Through a unique rolling technique developed by us, the spade blade is rolled conically and is thus self-sharpening.